Case Studies

Although we handle a wide variety of clients, the following user case studies will serve to underscore some of the value-added services that we have been able to provide over the years. Please be aware that we strive to constantly give each of our clients a full service, customized solution to all of their needs.

SHIPMENT VISIBILITY & ANALYTICS

Custom shipment tracking and supply chain analysis.

Top 100 Importer - Major Electrics Company

Client Background:

Leading manufacturer and wholesaler of consumer and business related electronics.

Client Footprint:

In addition to North America, client warehouses and distributes to over 50 countries and maintains substantial market share in high end product lines.

Challenge:

Client’s legacy supply chain systems (manual & multiple service providers systems) developed inefficient processes, created redundancy and inconsistent reporting.

Solutions

- Evaluate each business units’ needs of performance metrics.

- Carrier Performance, Landed Costs, Event Management, Vendor Management

- Develop business unit KPI’s based on performance metrics.

- Consolidate supply chain data management in American Shipping data centers.

Results

- Single data source reduced errors, commissions and redundancy by 27.5% within 12 months.

- KPI’s allowed client to replace under- performing carriers resulting in a current on-time performance of 98.3% (an improvement of 19% prior to implementation.)

- KPI’s improved purchasing strategies reducing non- performing categories and increasing inventory turns from 4.2 to 4.7 on higher profit categories.

Food Industry Importer/Manufacturer

Client Background:

Leading manufacturer and wholesaler of food products

Client Footprint:

Client serves the USA food retailers

Challenge:

Due to the complexity of individual business units the client required a process/system to eliminate manual record keeping and deliver, electronically, all documentation to comply with CBP and OGA requirements

Solutions

- Electronic “checklist” utilized by all American Shipping and client locations providing real time confirmation of document receipt.

- Customized file structures for business unit reporting

Results

- Client operates in a “paperless” environment allowing for distribution of personnel to other areas in the company to drive growth.

- Converted space previously utilized for document retention to manufacturing allowing for increased production and overhead absorption.

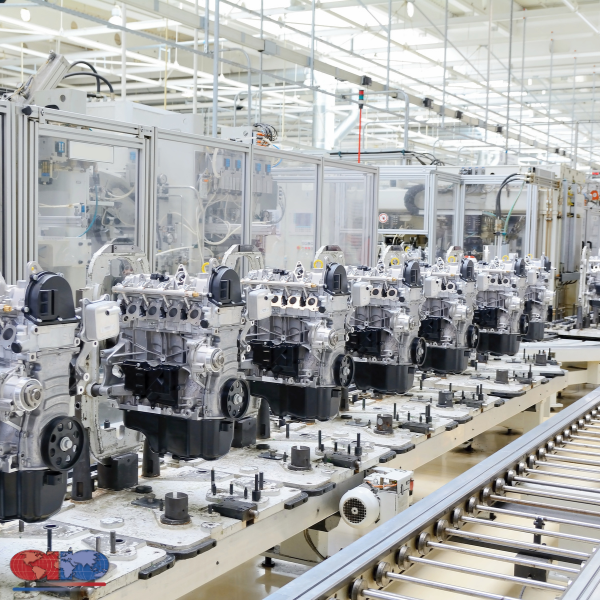

Automotive and Consumer Electronics Company

Client Background:

Leading manufacturer and wholesaler of automotive electronics and accessories

Client Footprint:

Under both named and private branding, client serves as a tier 1 supplier to the automotive industry and wholesaler to “big box” retailers.

Challenge:

Client’s legacy supply chain system was limited in functionality and was unable to produce customized financial and supply chain event reporting.

Solutions

- Evaluate each business units’ data element requirements.

- Shared development with clients IT group to integrate their ERP system with American Shipping operating systems.

- Consolidate supply chain data management in American Shipping data centers.

Results

- Single data source feeds real time, product specific information to clients ERP system allowing client to adjust inbound receipt locations. This feature reduces “touch points” thereby reducing costs and speed to client.

- Client captures landed cost at SKU level improving visibility of purchase price variances which creates efficiencies for cost accounting and product managers.

Food Industry Importer/Manufacturer

Client Background:

A leading manufacturer and wholesaler of canned seafood products.

Client Footprint:

Client’s products are distributed and sold in over 115 countries.

Challenge:

Client needed enhanced reporting to track SKU level data based on products production date in order to comply with various countries consumer product laws.

Solutions

- Capture SKU level data and production date electronically for each shipment

- Prepare all US Customs entries at lowest product level (production date code) then “sum” all production date codes by “like” HTS code for filling purposes with US Custom.

Results

- Client can now trace each shipment back to specific production date insuring quality and product integrity within the entire supply chain.

- Summary filing by HTS code reduced entry fees by 13% on an annualized basis.

Manufacturer & Wholesaler of Home Improvement Pneumatic Tools and Accessories

Client Footprint:

In addition to North America, client warehouses and distributes to over 20 countries and maintains substantial market share in both home owner & professional contractor categories.

Challenge:

Client’s growth created a huge strain on the management of inventory for raw materials, sub-assemblies and finished goods resulting in excess inventory and reduced products turns.

Solutions

- Created an SKU database (raw materials, sub-assemblies and finished goods).

- Created an EDI interface between clients ERP (JD Edwards) and TAC operating system allowing for the flow of supply chain transactions. (304,310,850, 856, etc…)

- Created timing “triggers” in the supply chain that would alert client as to potential inventory deficits/overages.

- Consolidate supply chain data management in TAC data centers.

Results

- Within 12 months of program launch, client was able to eliminate 37% of slow moving and obsolete inventory.

- Replenishment of lower level SKU inventory driven by system data (inventory triggers) allowing for greater focus on higher performing SKU’s.

- Within 12 months of program launch, we improved vendor shipping performance by 18% and 8 years later vendors operate at 98.4% on time.

- Reduced clients timing for NAFTA certification from 12 to 2 weeks.

- Created tools to implement a paperless Duty Drawback Program.

What Our Clients Say

End to End Transparency

“The end-to-end transparency has allowed us to make Logistics decisions to lower costs such as storage at port and the ability to reroute our freight to another port if a pattern of congestion. One report in AmeriReports that actually helps with this is the “Ocean Carrier Transit Times with delivery”. We are able to track from the sail date to the delivery date. We are able to spot patterns of much longer transit times and investigate as to what the issue is and where we can make improvements.”

- Jennifer, Sur-Seal

Enhanced Shipping and Logistics Forecasting

“AmeriSystems has given us the ability to improve our inbound weekly DC forecasting allowing us to better plan labor needs and avoid unnecessary network cost.”

- Kyle, Chicken of the Sea Int'l

Optimized 3PL Operations and Real-Time Cargo Tracking

“Ameriweb and AmeriReports are used by our team on a daily basis. American Shipping has customized and automated reports that are transmitted via email to both internal and external teams. These reports are pivotal in daily operations and have improved efficiencies in our 3PL operations allowing them to anticipate inbound volumes expected and prep inbound receiving documents from one source. AmeriWeb has also proven to be a great tool to find out the current location of shipments and expected arrivals.”

- Dave, Sharp Electronics Corp.

Streamlining Global Supply Chain with Advanced Technology

"AmeriWeb and AmeriReports are invaluable resources for information on our shipments. These tools allow us to track our cargo all the way from ISF filing to final delivery. Before using these tools tracking shipments from end-to-end was a hassle having to use several different methods to gather all of the information needed. AmeriSystems has it all in one place.”

- Ryan, Pioneer Electronics

Critical Insights for Freight Management and Efficiency

“Being able to access up to the minute information is very critical in situations where customer orders are on a tight timeline. With the current state of the Panama Canal we are using this system multiple times a week.”

- Lisa, Kids Preferred

Unmatched Customs Clearance and Delivery Services

“We are thoroughly pleased with the constant attention given to our account and how this company ensures smooth and efficient custom clearance and delivery - we would definitely recommend using American Companies for any and all of your shipping needs.”

- Jolene, Blue Ridge Home Fashions Inc.

Immediate and Efficient International Logistics Solutions

“The American Companies is the one Company I would & have recommended to other importers. I forward the paperwork for air and ocean shipments and things are taken care of immediately. I get my necessary reports without fail by the end of day.I thank them for the wonderful work they all are doing.”

- Anthony, The Janssen Boas Company

Expertise in Global Shipping and Compliance

“We have been using American Shipping as our import broker for many years and have found them to be very efficient and economical. Their service is excellent and it is a pleasure to work with their staff. In addition their overseas agents are also very professional especially regarding complying with ISF requirements. We enthusiastically recommend them.”

- Rene, Hunter Industrial

Contact Us

Fill out your information below and a member of our team will reach out to you!